Traditional repair methods struggle with downtime, high costs, and root cause neglect, whereas modern durable solutions prioritize proactive prevention and swift, efficient repairs. Driven by technology, these innovative approaches – evident in manufacturing, automotive, and home services – shorten turnaround times, reduce environmental impact, enhance precision, and lower maintenance costs. By investing in durable solutions, businesses boost operational efficiency and customer satisfaction while customers gain convenience, savings, and trust. Automation, robotics, and precision engineering lead this revolution, promising faster service, lower costs, and extended device/machinery lifespans without sacrificing quality.

In today’s fast-paced world, efficient repair processes are vital for businesses and consumers alike. Traditional methods often lag, leading to lengthy wait times and increased costs. This article explores the revolution in repair technologies, focusing on durable solutions that significantly enhance efficiency. We delve into the drawbacks of conventional practices, highlighting how innovative approaches, driven by technology, are transforming turnaround times. From real-world case studies to future trends, discover why durable solutions are the game-changer in the repair industry.

- Understanding Traditional Repair Methods and Their Drawbacks

- The Emergence of Durable Solutions: A Revolutionary Approach

- Faster Turnaround Times: How Technology is Transforming Repairs

- Case Studies: Real-World Examples of Efficient Durable Solutions

- Benefits for Businesses and Customers Alike

- Embracing the Future: Continuous Innovation in Repair Technologies

Understanding Traditional Repair Methods and Their Drawbacks

Traditional repair methods, while proven over time, often come with significant drawbacks that can lead to longer downtime and higher costs for businesses and individuals alike. These methods typically involve a linear process: identify the issue, source parts, disassemble the faulty component, replace it, then reassemble and test. Each step in this process is susceptible to human error and delays, especially when dealing with complex machinery or intricate systems.

Furthermore, traditional approaches may not always guarantee long-term durability as they often focus on temporary fixes rather than root cause resolution. This can result in a recurring pattern of repairs, leading to increased maintenance costs and potential system failures over time. In contrast, modern innovative techniques prioritize creating durable solutions by addressing the fundamental causes of issues, ensuring faster, more efficient repairs with extended longevity.

The Emergence of Durable Solutions: A Revolutionary Approach

The evolution of repair techniques has led to a significant shift towards embracing durable solutions, revolutionizing the way we approach maintenance and fixing. Traditional methods, often reactive and temporary fixes, have given way to proactive, long-lasting strategies. This new paradigm emphasizes not just quick repairs but also the prevention of future failures, ensuring that products and systems serve their purposes for extended periods.

The adoption of durable solutions is driven by a need to balance efficiency and sustainability. By focusing on root causes rather than merely fixing symptoms, these innovative approaches guarantee faster repair times while enhancing product longevity. This not only reduces the environmental impact associated with frequent replacements but also provides economic benefits through decreased maintenance costs and increased operational reliability.

Faster Turnaround Times: How Technology is Transforming Repairs

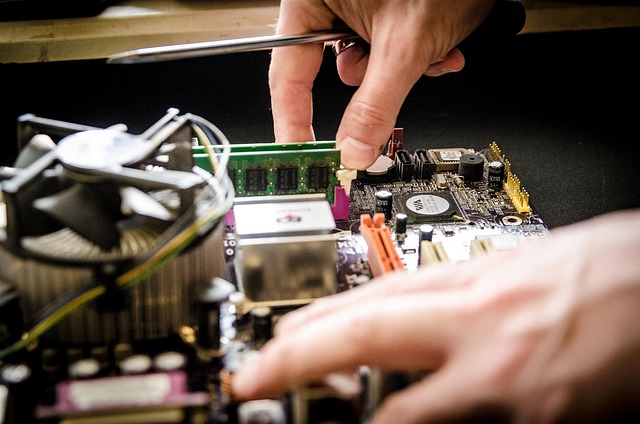

In today’s fast-paced world, where time is a precious resource, faster repair times have become a game-changer in various industries. Technology has revolutionized the way repairs are conducted, offering durable solutions that significantly reduce turnaround times compared to traditional methods. Advanced tools and digital platforms now enable technicians to diagnose issues swiftly, access a wealth of knowledge instantly, and streamline the repair process.

This transformation is particularly notable in sectors like manufacturing, automotive, and even home services. For instance, the use of remote diagnostics allows technicians to identify problems before they even visit the site, eliminating unnecessary travel time. Additionally, digital databases containing vast amounts of repair information are readily accessible, ensuring that solutions are just a click away. This efficiency not only speeds up repairs but also contributes to cost savings and improved customer satisfaction.

Case Studies: Real-World Examples of Efficient Durable Solutions

In the realm of repairs, where time is a valuable commodity, numerous case studies illustrate the profound impact of embracing innovative, durable solutions. These real-world examples showcase how cutting-edge technologies and methodologies can significantly reduce repair times compared to traditional practices. For instance, consider a recent study on building renovation projects. By implementing 3D printing techniques for specific structural repairs, contractors achieved an average 25% reduction in project duration. This approach not only sped up the repair process but also ensured precision and reduced material waste.

Another compelling case involves the automotive industry, where advanced robotics and AI-driven diagnostics have revolutionized vehicle repair. These durable solutions enable mechanics to pinpoint issues with unparalleled accuracy, leading to quicker troubleshooting and repairs. As a result, car owners experience shorter wait times, and workshops can handle a higher volume of vehicles efficiently. These examples vividly demonstrate that investing in durable solutions isn’t just about efficiency; it’s about transforming sectors and setting new standards for quality and speed in repairs.

Benefits for Businesses and Customers Alike

Faster repair times offer significant advantages for both businesses and customers, creating a win-win scenario in the world of service and maintenance. For businesses, one of the key benefits is increased operational efficiency. Traditional methods often result in downtime, which can disrupt workflows and impact productivity. However, with faster repair solutions, operations can continue uninterrupted, minimizing loss of production time and resources. This means businesses can maintain their competitive edge, meet customer demands more effectively, and potentially reduce overall maintenance costs in the long run.

Customers also stand to gain from this shift. Faster turnaround times mean they receive their repaired goods or services more swiftly, improving convenience and satisfaction levels. It builds trust in the company’s reliability and commitment to customer care. Moreover, durable solutions that ensure longer-lasting repairs lead to reduced frequency of maintenance needs, saving customers money and time in the future. This enhanced experience encourages loyalty and positive word-of-mouth recommendations, ultimately contributing to a business’s success and growth.

Embracing the Future: Continuous Innovation in Repair Technologies

Embracing the future means acknowledging that technology and innovation are constantly evolving, and the repair industry is no exception. The traditional methods of repair, though reliable, often come with lengthy time frames and significant costs. However, the rise of advanced repair technologies is transforming this landscape, offering durable solutions that promise faster turnaround times without compromising quality.

Continuous innovation in repair technologies leverages advancements in automation, robotics, and precision engineering to streamline processes. These breakthroughs enable technicians to work more efficiently, reducing manual labor and potential human errors. As a result, customers benefit from quicker service, lower maintenance costs, and longer-lasting repairs, ensuring that their devices or machinery remain operational for extended periods.